Transparent Prices

Discover our flexible pricing models to suit your company.

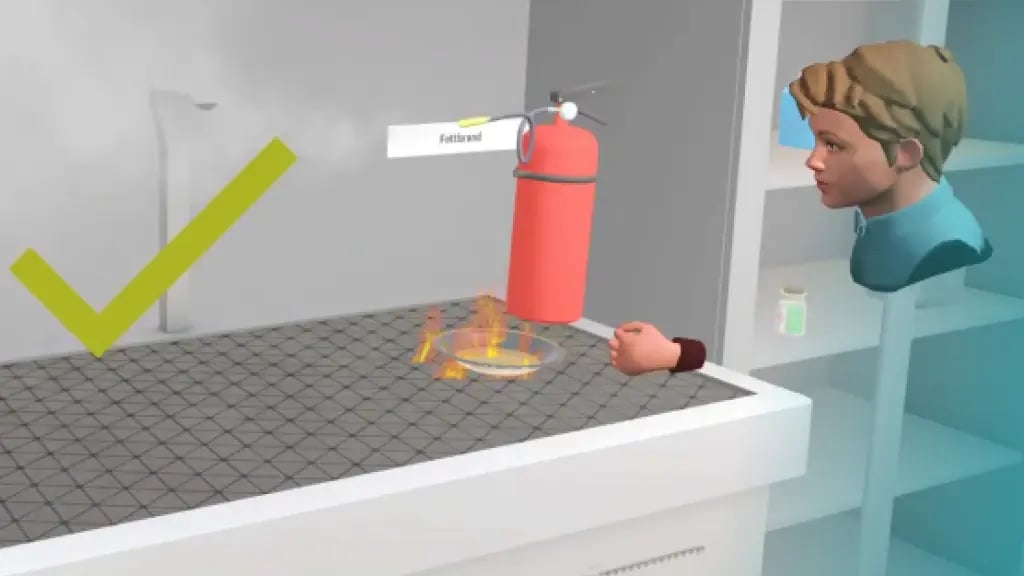

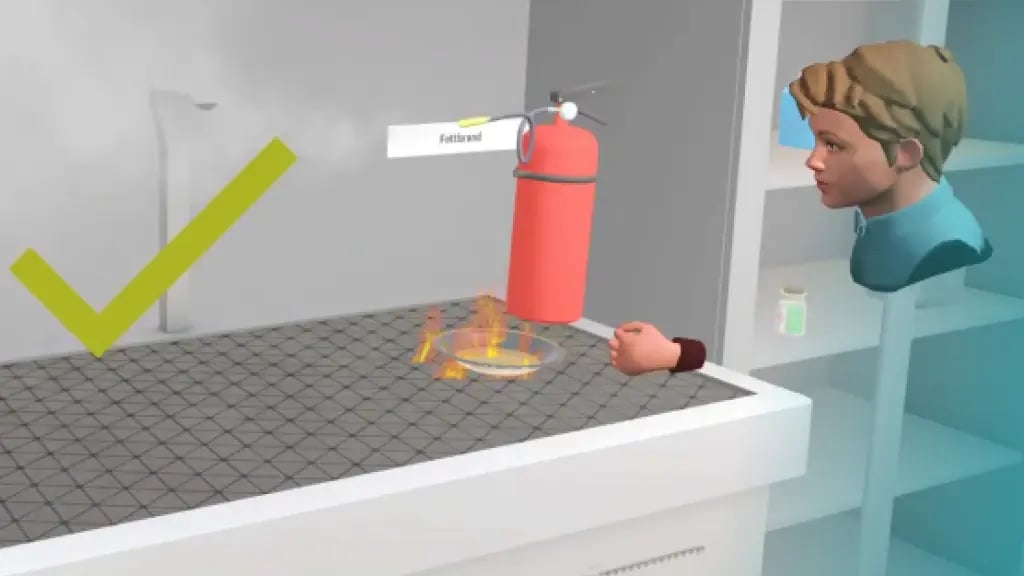

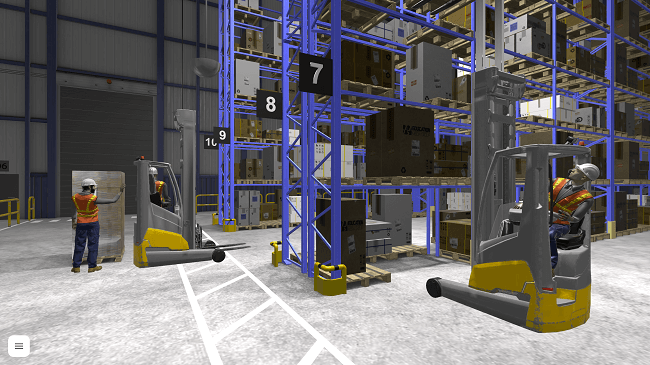

Raise the safety standards in your labs with immersive learning environments many times over.

Are you looking to ensure your employees are well-prepared for emergencies?

Our AI-driven immersive training courses offer practical simulations that make your teams fit for emergencies and sustainably improve compliance with safety regulations.

Learn how to raise safety standards in laboratories.

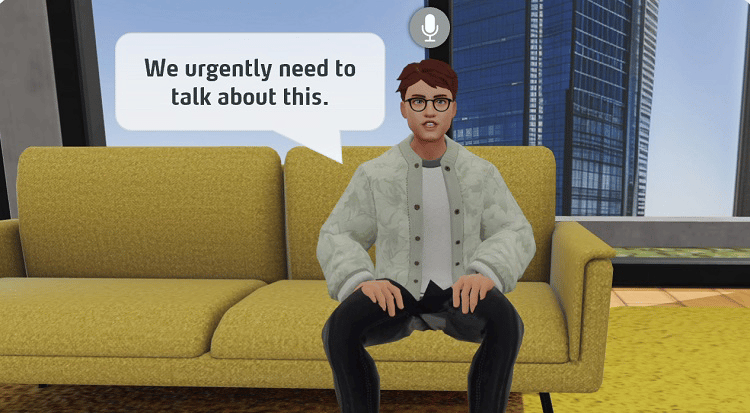

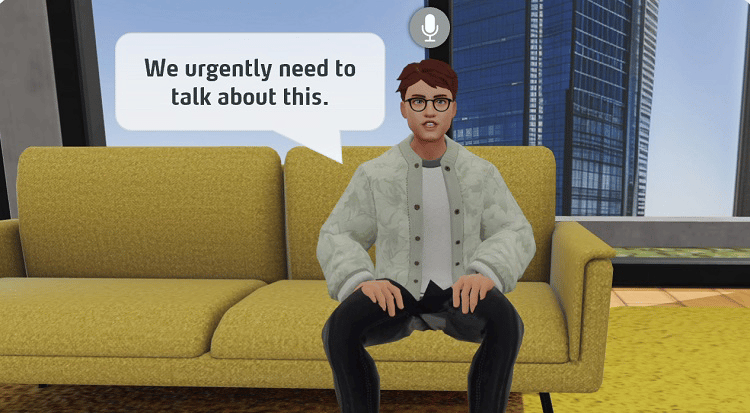

Employees are trained in basic communication techniques to avoid misunderstandings and optimize teamwork promoting a productive and harmonious working environment.

3 units + 1 exam (approx. 80 min. study time)

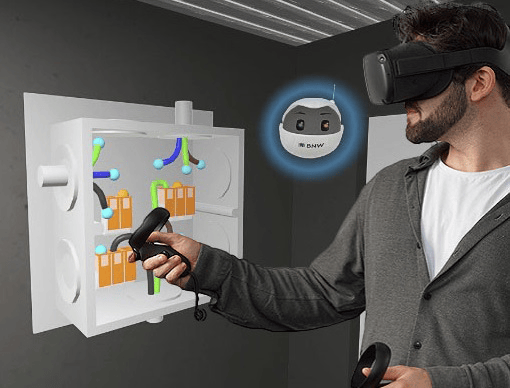

Discover how the leading pharmaceutical company Boehringer Ingelheim uses Virtual Reality to promote hands-on and safe learning without using scarce resources in previously inaccessible laboratories.

Pfizer's VR training in continuing medical education is designed to shorten treatment times for stroke patients and ensure efficient and practice-oriented training.

All training courses can be customized to your individual needs with our included No Code Editor. Just with a few clicks and without programming.

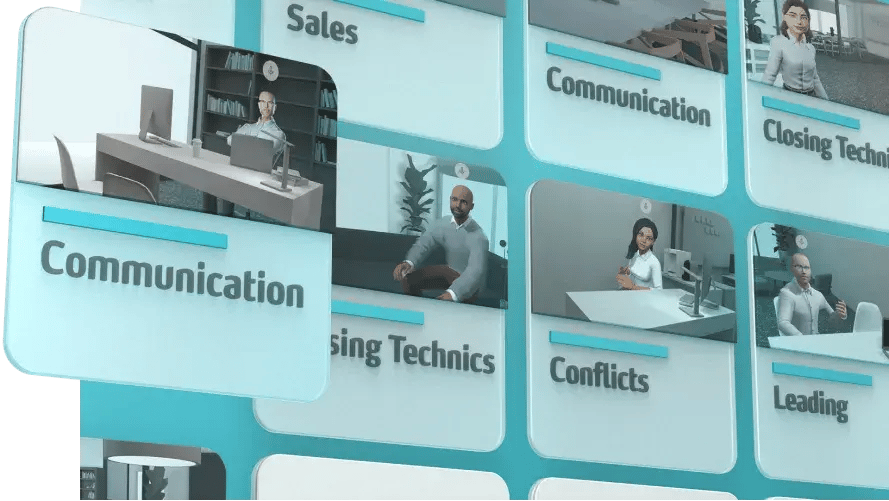

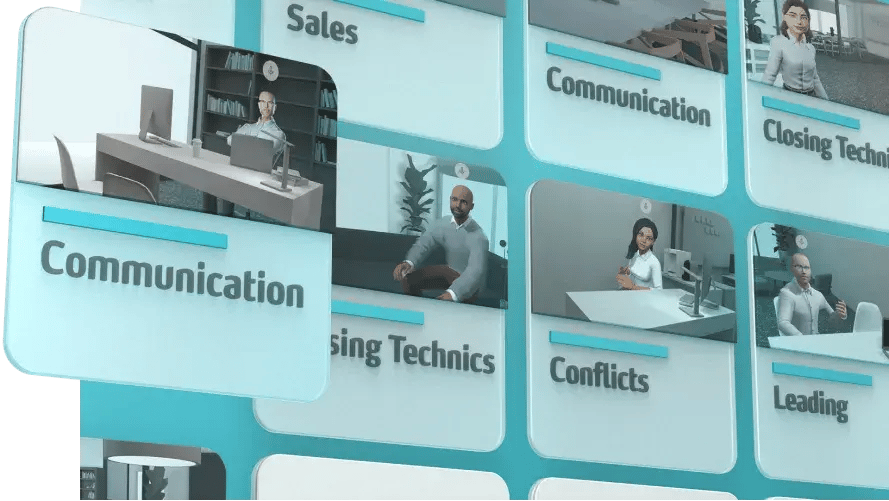

Benefit from our extensive course library with lots of free content delivered directly with our platform. Discover the full range for your training courses now.

We offer customized training units that are individually tailored to the needs of your customer service employees.

Learn how to raise safety standards in laboratories.

Employees are trained in basic communication techniques to avoid misunderstandings and optimize teamwork promoting a productive and harmonious working environment.

3 units + 1 exam (approx. 80 min. study time)

Discover how the leading pharmaceutical company Boehringer Ingelheim uses Virtual Reality to promote hands-on and safe learning without using scarce resources in previously inaccessible laboratories.

Pfizer's VR training in continuing medical education is designed to shorten treatment times for stroke patients and ensure efficient and practice-oriented training.

All training courses can be customized to your individual needs with our included No Code Editor. Just with a few clicks and without programming.

Benefit from our extensive course library with lots of free content delivered directly with our platform. Discover the full range for your training courses now.

We offer customized training units that are individually tailored to the needs of your customer service employees.

All training courses can also be accessed in a web browser without installation.

Trusted by companies looking for measurable progress and real change.

Whether it's planning or successfully implementing your learning projects: 3spin Learning supports you every step of the way and ensures that complex learning is simple and effective.

Discover our flexible pricing models to suit your company.

Product insights

Specific assessment of your particular requirements

Hands-on industry-specific case studies